Are you looking for ways to optimize your supply chain operations and reduce costs? Then don’t overlook the importance of reverse logistics.

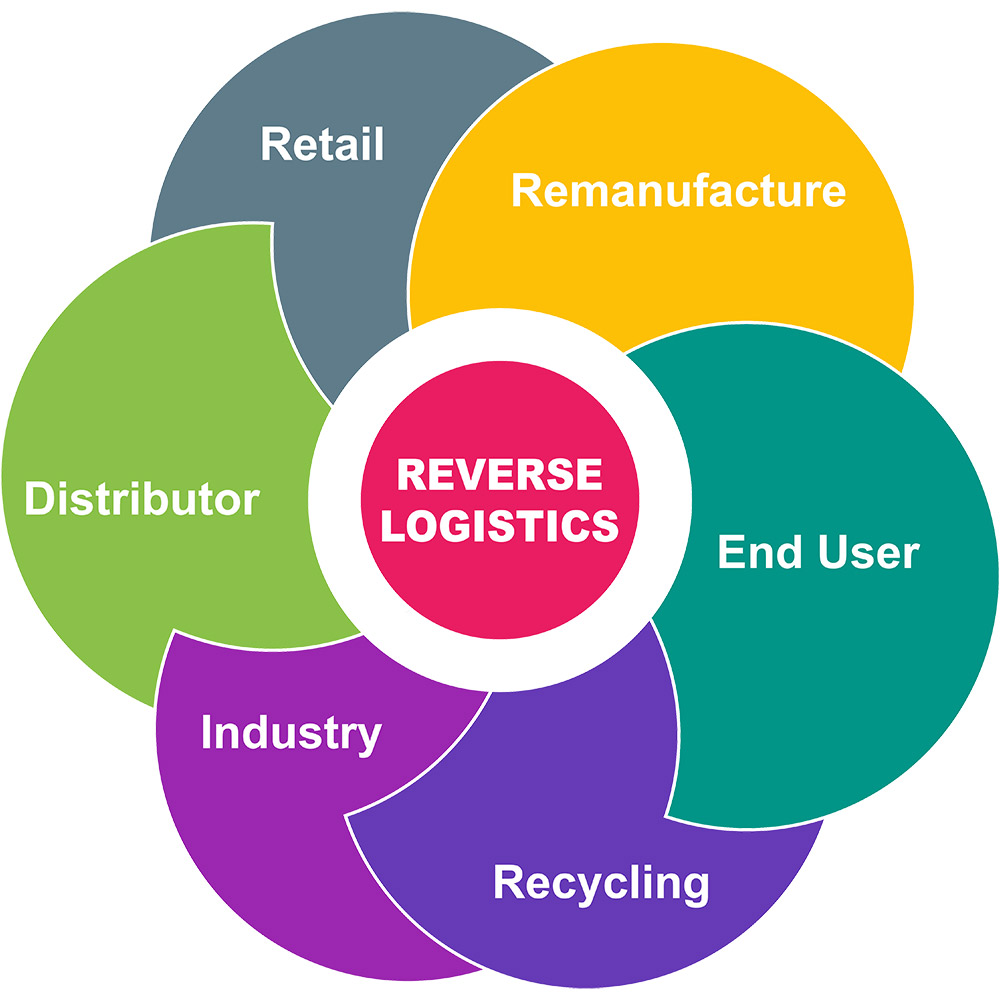

Reverse logistics plays a crucial role in the supply chain, as it helps to manage the flow of goods and materials in a more efficient and sustainable way. By implementing effective reverse logistics processes, companies can reduce waste, minimize environmental impact, and improve customer satisfaction. Moreover, reverse logistics also helps to reduce costs by allowing you to recover value from returned products and materials.

In this article, we’ll explain the importance of reverse logistics in today’s supply chain. You’ll also find practical tips on how to optimize reverse logistics operations and overcome challenges for maximum efficiency.

So let’s get right into it!

The Importance of Reverse Logistics Management in Today’s Supply Chain

Reverse logistics plays a crucial role in your supply chain. It involves managing the flow of goods from the point of consumption back to the point of origin, including product returns, refurbishing, recycling, and disposal.

By implementing effective reverse logistics management processes, you can optimize the flow of goods and materials in a more efficient and sustainable way.

Reverse logistics helps you reduce costs by allowing you to recover value from returned products and materials. You can avoid the costs of producing new items by refurbishing or reusing returned products, and you can reduce waste disposal costs by optimizing reverse logistics processes.

Overall, reverse logistics management is an essential component of your supply chain that can benefit your business and the environment alike.

Four Steps to Optimize Your Reverse Logistics Operations For Maximum Efficiency

Efficient reverse logistics operations can help you minimize costs, improve customer satisfaction, and reduce environmental impact. To optimize your reverse logistics operations for maximum efficiency, you need to focus on the following:

- Effective planning and management

- The use of technology and automation

- Collaboration with partners

- Continuous improvement

Let’s review each step one by one.

Step #1. Effective Planning and Management

The first step to optimizing your reverse logistics operations is effective planning and management. This involves creating a clear and comprehensive reverse logistics plan that outlines the processes and procedures for handling returned products, refurbishing, recycling, and disposal. You also need to establish performance metrics and key performance indicators (KPIs) to monitor the efficiency of your reverse logistics processes.

Step #2. Use of Technology and Automation

The second step is the use of technology and automation. This includes the implementation of a robust reverse logistics software system that can automate processes, provide real-time visibility, and improve inventory management. Automation also eliminates errors and reduces the time and cost associated with manual processes.

Step #3. Collaboration with Partners

The third step is a collaboration with partners. You need to work closely with your partners, including suppliers, distributors, and logistics providers, to streamline the reverse logistics process. This can involve creating a clear communication plan, establishing performance metrics, and sharing data to optimize the flow of goods and materials.

Step #4. Continuous Improvement

The final step is continuous improvement. To optimize your reverse logistics operations, you need to continually review and improve your processes. This involves analyzing performance metrics and KPIs, identifying areas for improvement, and implementing changes to improve efficiency and reduce costs. By following these four steps, you can optimize your reverse logistics operations for maximum efficiency and achieve your business goals.

Partnering with a Reverse Logistics Service Provider

Partnering with a reverse logistics service provider can help you optimize your reverse logistics operations for maximum efficiency. As a reverse logistics solution, we have the expertise and resources to manage the entire reverse logistics process, from product returns to refurbishing, recycling, and disposal. At Haulers Logistics, we also offer data and insights to help you make data-driven decisions and reduce costs.

By leveraging our expertise and extensive relationships with reliable carriers, you can focus on your core business operations while improving sustainability and reducing costs.

Common Challenges in Reverse Logistics and How to Overcome Them

There are a few challenges you may face after implementing reverse logistics into your supply chain. Let’s review two common challenges and ways to overcome them.

Challenge #1. Product Returns Management

Managing product returns logistics can be time-consuming, costly, and frustrating, especially if you don’t have a standardized process in place.

Solution:

To overcome this challenge, it’s essential to have a well-defined transportation and logistics management process. This process should include clear communication with carriers, outlining your expectations and requirements for handling returns. It should also include a system for tracking shipments and monitoring their progress, ensuring that they arrive at their destination on time and in good condition.

Challenge #2. Inventory Management

Managing inventory can be complicated when dealing with returned products of varying conditions and quantities.

Solution:

To overcome this challenge, it’s essential to have an effective inventory management system. This system should include a process for inspecting and grading returned products, identifying products that can be refurbished or resold, and separating products that need to be recycled or disposed of.

Using technology can also help optimize inventory management. Implementing a warehouse management system can help you automate inventory management processes, such as tracking product location, managing inventory levels, and optimizing storage space.

Top Benefits of Implementing a Reverse Logistics Strategy in Your Business

Implementing a reverse logistics strategy in your business can provide several benefits, from increasing customer satisfaction to improving sustainability and profitability. Let’s take a closer look at some of the top benefits.

Increased Customer Satisfaction

A well-defined reverse logistics strategy can help you efficiently handle product returns and exchanges, which can lead to increased customer satisfaction. Providing a hassle-free returns process can help you build trust and loyalty with your customers, leading to repeat business and positive reviews.

Reduced Costs and Increased Profitability

An effective reverse logistics strategy can help you reduce costs associated with product returns, including transportation, warehousing, and processing costs. Additionally, by refurbishing and reselling returned products, you can generate revenue and increase profitability.

Improved Sustainability and Environmental Impact

Implementing a reverse logistics strategy can also help you improve sustainability and reduce your environmental impact. By refurbishing and reselling returned products, you can reduce waste and conserve resources. Additionally, by properly disposing of products that cannot be resold, you can reduce environmental harm.

Competitive Advantage and Differentiation

Companies that have a well-defined reverse logistics strategy can differentiate themselves from competitors by offering a hassle-free returns process and sustainable practices. This can lead to increased brand loyalty and customer satisfaction.

Increased Visibility and Control Over the Supply Chain

A reverse logistics strategy can also provide increased visibility and control over your supply chain. By tracking returned products, you can identify trends and areas for improvement, enabling you to make data-driven decisions to optimize your operations.

Ready to Implement Reverse Logistics?

In conclusion, it’s clear that reverse logistics plays a crucial role in today’s supply chain. By embracing reverse logistics, you can not only reduce your business costs but also enhance its sustainability, customer satisfaction, and competitive advantage.

Implementing an efficient reverse logistics strategy may be challenging, but by following the recommended steps, you can optimize your supply chain operations and reap the benefits. And if you haven’t already, it’s time to embrace reverse logistics and partner with a reliable service provider to help you navigate the challenges and maximize the results.

Contact Haulers Logistics today to streamline your reverse supply chain needs and maximize your supply chain potential.

Building relationships one client at a time. Put our 65 years of combined industry experience to work for you!

In today's fast-paced business environment, partnering with a trusted logistics provider like Haulers Logistics can make all the difference in achieving your goals and staying ahead of the competition. Our expertise in handling complex supply chain operations, coupled with our commitment to delivering exceptional customer service, makes us the ideal partner for businesses of all sizes and industries. By choosing Haulers Logistics for your logistics needs, you gain access to our experienced team, state-of-the-art technology, and extensive network of resources, ensuring that your products are delivered to their destinations on time and in perfect condition.

At Haulers Logistics, we understand that each client's logistics requirements are unique, and we pride ourselves on providing customized, end-to-end solutions that address your specific needs. Our innovative approach to logistics management not only streamlines your supply chain operations but also offers valuable insights for continuous improvement and growth. By leveraging our industry knowledge, advanced analytics, and cutting-edge technology, we help you optimize efficiency, reduce costs, and enhance your brand's reputation in the market. Trust Haulers Logistics to be your dedicated logistics partner, and experience the benefits of our expertise, flexibility, and commitment to your success.

Don’t take a chance ... call 714.369.2188 or Email Haulers Logistics today and get your freight job done right. Our work is guaranteed ... we won't stop until the job's done right and to your satisfaction!

Want to learn more?

Curious about Haulers Logistics' prices and services?

Would you like a free quote?

Have a question?